The Institute for Operations and Technology Management (IBT) at the Birkenfeld Environmental Campus is planning to merge several local, mainly metalworking companies from the Hunsrück-Hochwald region into the Rapid Prototyping project consortium. In the joint research project "Resource Efficient Rapid Prototyping" (RERAP), the focus will be on the scientific investigation and the development of competencies for energy and resource efficiency through generative manufacturing processes (3D printing). Here, innovative production techniques of the entire manufacturing process from the idea to the finished component are examined by the Trier University of Applied Sciences.

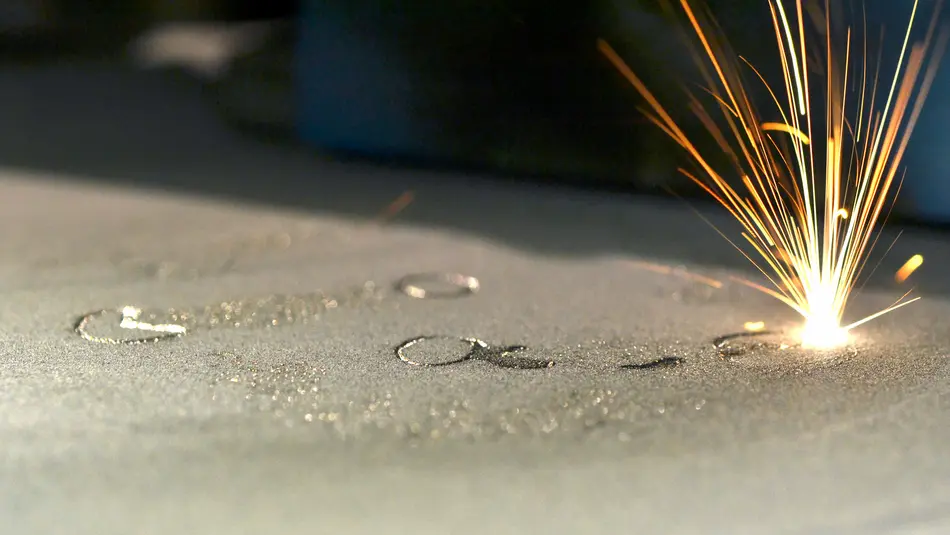

A central goal of the project is the development of competence from the comparison of conventional and generative manufacturing processes with regard to energy and resource efficiency and the influence of efficiency optimization on workpiece quality. For this purpose, different components are defined in scientific discussions with the project partners, digitally constructed and finally both conventionally with a machine tool and generatively by the laser sintering process (SLM) (i. e. the three-dimensional printing of workpieces by melting metal powder using a laser) with an SLM machine. Both processes are compared with respect to the specific properties of the component from the point of view of the use of energy and resources in order to draw conclusions about the limits and potentials of the manufacturing processes for increasing efficiency.

The project also aims to derive generally applicable rules and definitions for the optimization of production processes from research projects with the SLM machine by analyzing heterogeneous product and production processes for their efficiency improvement potential in terms of energy consumption and resource usage and optimizing them in particular by integrating generative manufacturing processes.

| Consortium | Trier University of Applied Sciences (Birkenfeld Environmental Campus) |

| Duration | November 2018 - April 2021 |

| Funded by | European Union through the European Regional Development Fund (EFRE) under the objective “Investment for Growth and Jobs” (IWB) |

| Funding amount | € 579,415.85, share of Trier University of Applied Sciences: € 289,707.92 |

![[Translate to Englisch:] Logo RERAP Ressourceneffizientes Rapid Prototyping](/fileadmin/_processed_/8/4/csm_Logo_Rerap_5537afd0d6.webp)

![[Translate to Englisch:] EU mit Schriftzug europäische Union EFRE](/fileadmin/_processed_/8/4/csm_EU-Emblem_mit_Schriftzug_Europaeische_Union_EFRE_fc2e22fc64.webp)

You are leaving the official website of Trier University of Applied Sciences